Silevo introduces silicon PV that doesn’t wilt in the heat

Traditional silicon solar modules are affected by heat, losing efficiency as temperatures rise. But Silevo, by using techniques from thin-film photovoltaics (PV), is preparing to scale up production on silicon-based PV that’s much less impacted by temperatures.

Traditional silicon solar modules are affected by heat, losing efficiency as temperatures rise. But Silevo, by using techniques from thin-film photovoltaics (PV), is preparing to scale up production on silicon-based PV that’s much less impacted by temperatures.

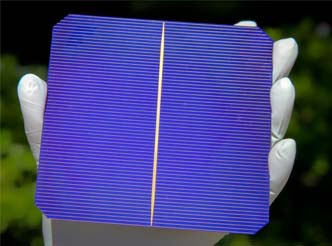

Silevo’s technology includes a number of innovations, like using a thin-film, doped amorphous silicon layer atop a proprietary tunneling junction oxidation layer, atop a crystalline silicon substrate layer. The electricity produced by this silicon sandwich is covered with a transparent conductive and copper electrodes to conduct the electricity, rather than silver-based electrodes, to help further reduce costs.

“We developed a hybrid, using a crystalline silicone substrate, then using some materials from thin-film technologies to drive low-temperature coefficient,” said Silveo’s Vice President of Business Development Chris Beitel. The low-temperature coefficient means that as it heats up, the modules’ performance aren’t impacted as much. As temperatures rise, the company’s Triex technology loses about 0.22 percent drop in efficiency per Celsius degree increase.

Conventional silicon solar can drop between 0.45 percent and 0.5 percent per Celsius degree increase. That means that at roughly 100 degrees Fahrenheit, a 200 watt silicon module will only produce about 160 watts of electricity, according to Beitel. Thin-film PV, like amorphous silicon and cadmium telluride-based PV isn’t affected as much. Co-opting that technology, Silevo’s PV cells produce between 5 percent and 12 percent more than conventional PV.

The result is a PV Cell that’s already about 20 percent efficient at converting sunlight into electricity, putting it in range of efficiency leaders like SunPower Corp. The company is now in pilot production at it’s Fremont, Calif., headquarters and Silevo is setting up its first commercial production plant in Hangzhou, China. Once completed this summer, the plant will produce 32 megawatts of modules annually at a cost of 98 cents per watt, Beitel said.

The company plans to quickly expand manufacturing capacity, to 200 megawatts in 2013 and 1 gigawatt shortly after that. “As we leverage the larger facility and take advantage of economies of scale, [costs will drop],” Beitel said. As soon as 2013, he projected that the price per wafered module could drop to 61 cents per watt.

At the same time efficiency of the modules is expected to increase. “We believe we can achieve 24 percent efficiency with volume and scale,” Beitel said.

The company is already delivering its products to customers for evaluation. It will first enter the residential and light commercial markets before pursuing utility-scale projects.