Nano layer makes solar panels self-cleaning

Seamus “Shay” Curran, director of the University of Houston’s Institute for NanoEnergy, doesn’t like cleaning windows.

Seamus “Shay” Curran, director of the University of Houston’s Institute for NanoEnergy, doesn’t like cleaning windows.

“My wife gets after me about it,” he said.

A new hydrophobic nano coating he and his team of researchers at UH have developed holds the promise of self-cleaning windows.

Of course, that’s just a pleasant byproduct. Curran developed the coating for, and expects to market it to, solar panel manufacturers.

“The maintenance of solar panels can become very costly,” he said.

When dirt and residue build up on the surface of a solar panel, it can diminish the panel’s efficiency by up to 30 percent, he said. If solar array owners don’t want that to add up in lack of productivity and lost revenue, they need to clean the panels.

“I don’t know about other places, but we get pollen here in Houston and it’s so bad I need to wash my car once a week if I’m going to see out the windshield,” Curran said.

The same is true for solar panels, he said. If they are to operate at their optimum level, they probably need to be cleaned every couple or few weeks. That can cost up $5 per panel.

“That might not sound like a lot,” he said. “But you get 52,000 panels and it adds up quickly.”

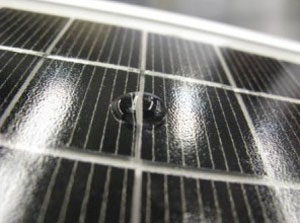

So, Curran and his researchers set out to find a way to cut back on solar panel maintenance and developed a nano coating. It’s eight nanometers, Curran said. That’s extremely thin and doesn’t scatter the light so it has no impact on the solar panel’s performance.

But the nanotechnology fills in all the hills and valleys in the glass where water settles. Water is the real reason panels get dirty, Curran said. It settles in part of the glass, attracts and holds dirt and then dries in place, leaving the dirty residue.

Curran’s coating makes the glass shed water. He said he wasn’t surprised the coating works, but he was impressed by how advanced it is. It repels salt water as well as fresh, which means it can also be used to protect aluminum framing in marine climates. And it stands up to the elements, he said.

The team completed testing in Ireland in June and the product is now in field trials in North Carolina.